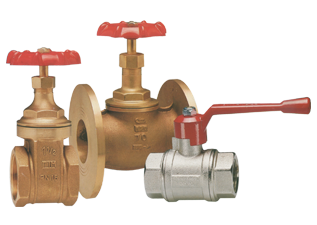

Brass and Bronze Valves

Quality Assurance

Company’s Quality System

The “Registered Firm Status” granted to us by BSI, Quality Assurance, and the SQ2 N. 0002/0 certificate granted by the “Instituto di Certificazione Industriale per la Meccanica” (ICIM), guarantee that CIM products are manufactured and tested in accordance with BS 5750 – Part 2: 1987 / ISO 9002-1987 / EN 29002-1987.

The word “quality” must be interpreted in the sense of a known and consistent “Quality Level” over a long period of time.

Therefore it not only refers to the product, but to the Company as a whole entity. Materials, plans, processes and working practices contribute to this aim; in a integral way, i.e. high product quality control throughout our Company.

Kembla® Copper Tube – Class X

| Nominal Diameter (mm) | Nominal Thickness (mm) | Maximum Working Pressures † -Annealed (kPa) | Maximum Working Pressures † -Half Hard (kPa) | Maximum Working Pressures † -Hard (kPa) | Mass / Length* (kg/5.8m) | Lengths/ Bundle | Lagged Tube -Kemline (mm) | Lagged Tube -Kemlag (mm) |

| 15 | 0.7 | 4500 | 5800 | 7100 | 1.63 | 100 | 15 | 15 |

| 22 | 0.9 | 3900 | 5100 | 6200 | 3.09 | 50 | 22 | 22 |

| 28 | 0.9 | 3100 | 4000 | 4800 | 3.98 | 50 | 28 | 28 |

| 35 | 1.2 | 3300 | 4200 | 5100 | 6.61 | 50 | 35 | 35 |

| 42 | 1.2 | 2700 | 3500 | 4300 | 7.98 | 50 | 42 | 42 |

| 54 | 1.2 | 2100 | 2700 | 3300 | 10.33 | 30 | 54 | |

| 66.7 | 1.2 | 1700 | 2000 | 2700 | 12.81 | 25 | 66.7 | |

| 76.1 | 1.5 | 1800 | 2400 | 2900 | 18.24 | 25 | 76.1 | |

| 108 | 1.5 | 1300 | 1700 | 2000 | 26.04 | 10 | 108 | |

| 133 | 1.5 | 1000 | 1400 | 1700 | 32.15 | 10 | ||

| 159 | 2.0 | 1200 | 1500 | 1800 | 51.18 | 5 |

† Based on individual tempers for temperature up to 65°C. Annealed values apply when tubes are softened during jointing or fabrication.

* Base on nominal diameter and thickness.

Sizes other than those listed above may be available upon request.

Kembla® Copper Tube – Class Y

| Nominal Diameter (mm) | Nominal Thickness (mm) | Maximum Working Pressures † -Annealed (kPa) | Maximum Working Pressures† -Half Hard (kPa) | Maximum Working Pressures† -Hard (kPa) | Mass / Length* (kg/5.8m) | Lengths/ Bundle | Lagged Tube Kemline (mm) | Lagged Tube Kemlag (mm) |

| 15 | 1.0 | 6700 | 8700 | 10 400 | 2.28 | 100 | 15 | 15 |

| 22 | 1.2 | 5300 | 6900 | 8400 | 4.07 | 50 | 22 | 22 |

| 28 | 1.2 | 4200 | 5500 | 6500 | 5.24 | 50 | 28 | 28 |

| 35 | 1.5 | 4100 | 5400 | 6500 | 8.19 | 50 | 35 | 35 |

| 42 | 1.5 | 3400 | 4500 | 5400 | 9.90 | 50 | 42 | 42 |

| 54 | 2.0 | 3600 | 4700 | 5600 | 16.95 | 30 | 54 | |

| 66.7 | 2.0 | 2800 | 3700 | 4500 | 21.09 | 25 | 66.7 | |

| 76.1 | 2.0 | 2500 | 3300 | 3900 | 24.15 | 25 | 76.1 | |

| 108 | 2.5 | 2200 | 2900 | 3400 | 42.99 | 10 | 108 |