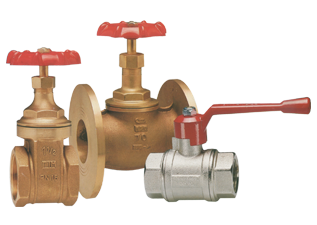

Malleable Iron Pipe Fittings

SA / TUPY manufactures the most complete line of Pipe Fittings in malleable cast iron used in the transportation of liquids, gases and fuse for residential, commercial and industrial use.

SA / Tupy’s pipe fittings, NPT threads are supplied in several types of surface finishing and according to domestic and international standards.

150 LBS and 300 LBS Galvanized Malleable Iron Pipe Fittings

– Threaded NPT (Brand:SA/TUPY)

Elbows 90°

AL 90, BL 90

Elbows 45°

AL 45, BL 45

Street Elbows 90°

AL 90, BL 90

Street Elbows 45°

ASL 45, BSL 45

Tees

AT, BT

Service Tees

AST, BST

Side Outlet Tees

ASOT, BSOT

Side Outlet Elbows

ASOL, BSOL

Couplings

AS, BS

Extension

AX, BX

Crosses/Reducing Crosses

ACR, BCR, ARCR, BRCR

Floor Flanges, Flanges “D”

AFF, FD

Round Flanges

F

Locknuts

ALN, LN

Wastenuts

AWN

Caps

ACA, BCA

Plugs

AP,P

Nipples

NI

Unions Conical Bras Seat

ACU, BCU

Reducing Unions

ARCU

Unions Flat Seat without Gasket

U

Unions Conical Iron to Iron Seat

U340

Unions Conical Iron to Iron Seat M&F

U341

Long Compression Couplings

ALCC

Short Compression Couplings

ASLCC

Bends M&F 90°

BMF 90

Bends M&F 45°

BMF 45

Bends Female 90°

BF 90

Bends Female 45°

BF 45

Cross Over

NOS

Reducing Elbows

ARL,BRL

Standard Specifications Malleable Iron Pipe Fittings

| Class | 150 lbs. | 300 lbs. |

| Materials | ASTM A 197.87 | ASTM A 197.87 |

| Dimensions | ANSI B 16.3-1998, B 16.14-1991 | ANSI B 16.39.1998, B 16.14-1991 |

| Union Dimensions | ASME B16.39.1998, DIN En 10242 | ASME B16.39.1998, |

| Threads | ANSI / ASME B 1.20.1 1983, ISO 7.1.1994 | ANSI / ASME B 1.20.1-1983 |

| Tensile Strength | ≥ 40,000 psi (28.4 kgf/mm²) | ≥ 40,000 psi (28.4 kgf/mm²) |

| Elongation | ≥ 5% | ≥ 5% |

| Zinc Coating | ASTM A 153/A 153M 1998 | ASTM A 153/A 153M 1998 |

| Working Pressure | 150 psing at 350°F | 300 psing at 550°F |